|

|

|

Model LH NFPA Low Pressure Hydraulic Cylinders |

|

|

"Adjustable Cushions" |

|

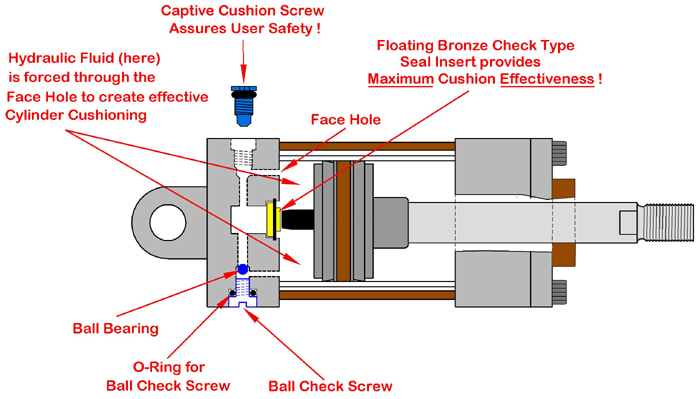

Peninsularís unique and improved cushioning system contains advanced engineering features that ensure effective cushioning of our low pressure hydraulic cylinders. Our industry proven and tested cushioning system will usually provide about four times the cylinder life as compared to a cylinder that is not cushioned, in those applications that contain stroke lengths in excess of three to four inches. Because of our cushion system design, thicker tie rod and tube diameters, a teflon backup ring around the OD of our rod cartridge and other important internal engineering features, our cylinders have significantly outlasted the competition in destructive type applications. Low pressure hydraulic cylinder adjustable cushions are internally designed features, by each cylinder manufacturer, that prevent the cylinder piston from slamming into the inside surface of the end cap at the end of the extended and retracted cylinder stroke. Our unique cushion design significantly enhances the cushioning system, and thereby increases the efficiency of the cushion effectiveness. By reducing the force of the impact of the piston slamming into the cylinder end cap, cylinder tie rod and piston rod failure due to fatigue is all but eliminated. Our adjustable cushion design also contains a captive cushion adjustment screw, a safety feature that prevents injury to anyone who may be loosening the cushion adjustment screw to control the end-of- stroke travel speed of the piston rod. The drawing below further illustrates how the Peninsular Model LH low pressure hydraulic cylinder cushion system works.

|

| Improved Peninsular Low Pressure Hydraulic Cylinder Cushion System Design |

|

Retracted Stroke Shown

The Ball Check system allows the piston to break out of cushion rapidly on the extended stroke |

|

Contact us toll free at (800) 526-7968 in the USA or Canada or at (586) 775-7211 or you may also e-mail us at sales@peninsularcylinders.com. |

|

|

|

Toll Free: 800-526-7968 Phone: (586)

775-7211 Fax: (586) 775-4545 |